Airtech Advanced Materials Group has been extruding and compounding resins for nearly 50 years and has expanded its offering with a game-changing line of unique resins for additive manufacturing. As Airtech continues to drive innovation, development, and testing in the additive manufacturing market, it has partnered with Thermwood Corporation to ensure its Dahltram® resins meet and exceed the requirements for 3D printing on the LSAM platform.

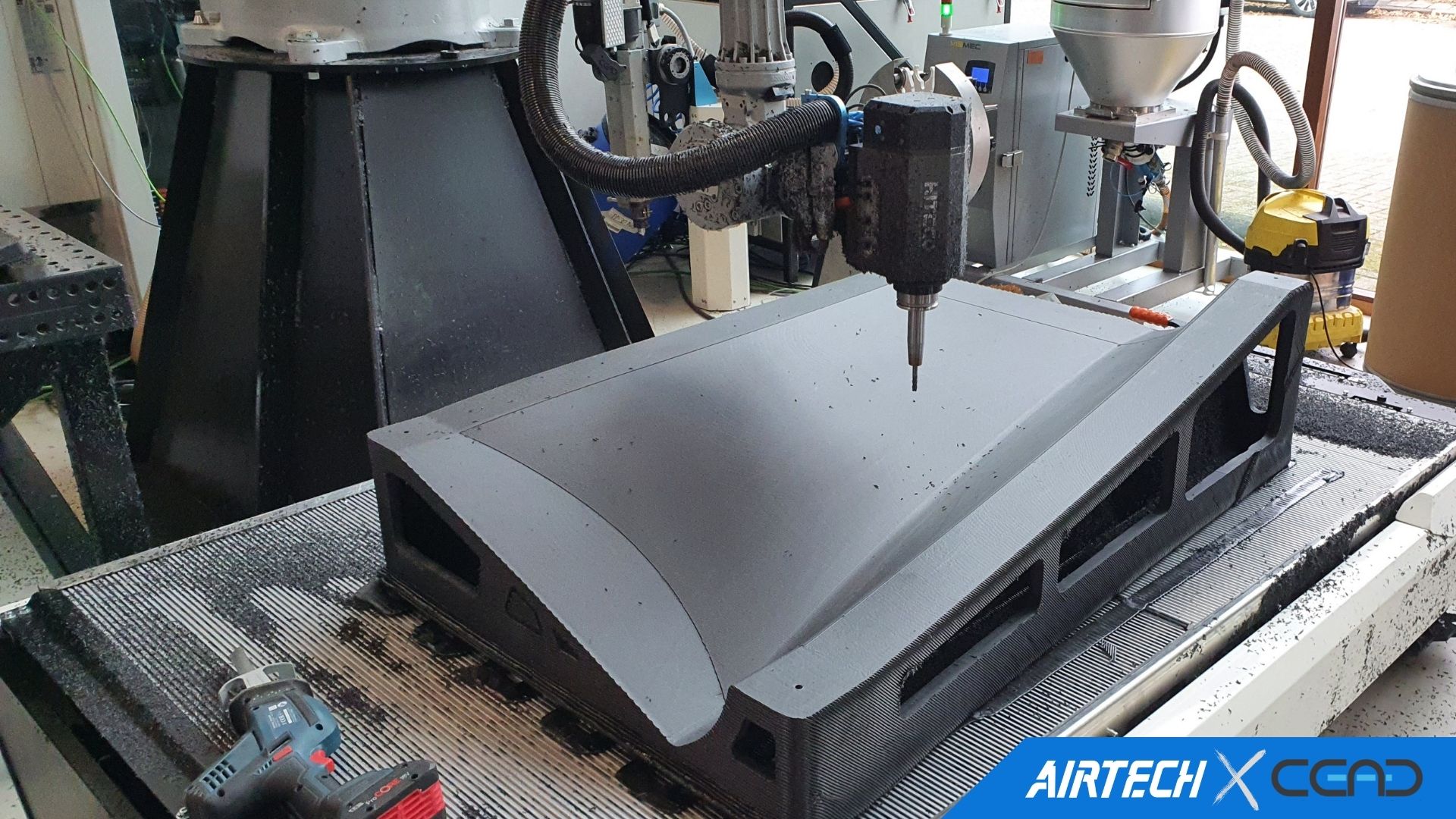

As a leading manufacturer of industrial large scale 3D printers and 5 axis routers, Thermwood’s LSAM technology delivers high-performance tooling, masters, patterns, molds and fixtures at high throughput to near net shape, with precision and vacuum integrity. As this partnership continues to produce technological advances, Airtech will actively maintain its collaboration with Thermwood in the development of new materials and expanded functionality.

In this industry-advancing collaboration, Dahltram® resins are used for large scale printing on Thermwood’s LSAM platforms; validating mechanical performance and performance in use at Airtech’s company headquarters. Airtech’s Dahltram® range of resins are suitable for multiple print platforms, providing production flexibility with end-use material validation. As this partnership supports advancements in additive manufacturing, Airtech has continued to demonstrate efficacy in composite fabrication with over 300 autoclave cycles completed to date. With extensive mechanical characterization data, Dahltram® resins are well suited for composite fabrication, as well as metal fabrication and direct to part applications.